Current location:Home > Ball pressing production line > Coal ball press production line

Current location:Home > Ball pressing production line > Coal ball press production line

Thoughtful and comprehensive, ensuring worry free purchasing for you~

We are a supplier of Coal ball press production line. Our Coal ball pressing production line is very popular in many countries. Our Coal ball briquette production line is carefully designed by the Kunteng technical team.

Tel:0086 17596531123

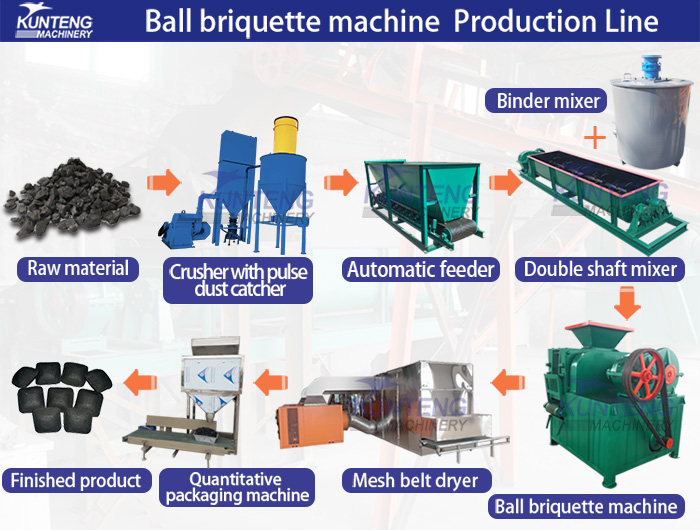

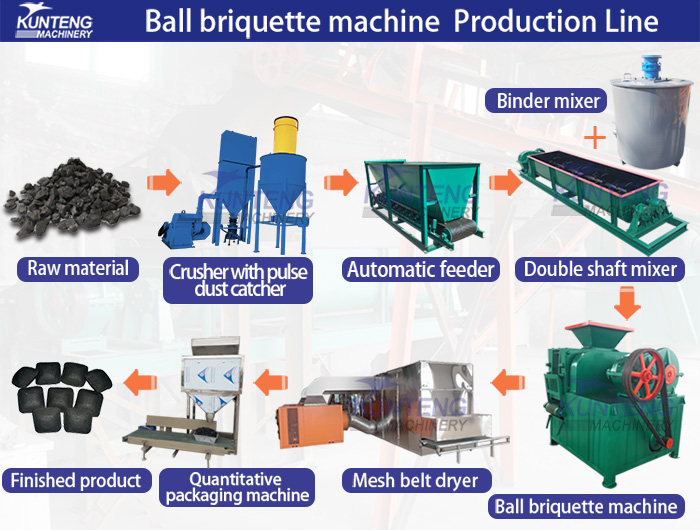

Production line of Coal ball press production line

--Crusher: if the charcoal size is bigger than 1cm, it will need crusher first.

--Feeder dosing machine: It can use forklift to feed materials,The function of feeder dosing machine is make whole line work uniform,There have binder silo install beside of feeder dosing machine, A certain amount of raw materials and binder enter the mixer together.

--Mixer machine: There have two purpose: 1.For some materials has no stickness,so for better making briquette, it need add some binder to increase the strength, the mixer machine can make the material and binder totally mix. 2. It can increase the density of material during mixing,it will be easy to make briquette.

--Mixed materials will transport to briquette making machine by conveyor. The size of briquette can design from 30-60mm,we can also make different shape according to your required.The capacity can process from 1-40 tons per hour.Our standard equipment is equipped with a hydraulic system and safety device. The pressure of our machine is adjustable, normally the working pressure is 40-50 tons.

--Drying machine: The formed briquette moisture around 25-30%, it can use drying machine to reduce moisture, the finished product can pack and sell directly.

--Packing machine: it can pack different weight bags according to client request, It's easy for transport.

Finished product of Coal ball press production line

Crusher description of Coal ball press production line

The coal powder crusher design with dust collector, when the machine working, it's no polluton. It can crush raw material size less than 1mm. It has screen control final powder size.

Mixer description of Coal ball press production line

This mixer suitable for high capacity production, continuous working. There are two shaft inside, in order to achieve sufficient contact between the powder and binder, thereby achieving better moulding effect.

Moulding machine description of Coal ball press production line

The coal ball roller press machine is also known as, strong ball pressing machine, mineral powder ball pressing machine, roller ball pressing machine, egg forming machine, and so on.

It can be used to press various powders and waste materials, such as coal powder, coking coal, carbon powder, carbon powder, activated carbon, coke powder, etc.

It can be pressed into various shapes, including round type,oval type, square,egg shaped, diamond shaped, pillow shaped and so on.

Mesh belt dryer Coal ball press production line

This Continuous Conveyor Multi Layer Mesh Belt Drying Machine can dry charcoal, coal, coke, carbon, mineral powder, iron powder, vegetables,grains,fruits,flowers and leaves,and tand industry products.At present, it has been used in drying more than 300 kinds of materials.

And it can use different heating sources, normally we have wood, coal, pellet, gas, electric.

The machine we have different sizes, we will provide machine offer according to client capacity.